Print Like a Pro: Understanding Dielines in Packaging

You’ve mastered your product and now it’s time to create the perfect package. Great, we’re here to help! There are many steps in the packaging production process, but you’ll have to start with a dieline.

So, what is a dieline? A dieline is a technical diagram that illustrates the lines a machine needs to know to print, cut, and fold a package design. Die lines aren’t just limited to packages, a dieline template is also used for folding sleeves, cartons, folders, and more. Packaging designers and computer aided designers are typically known to create die lines, sometimes with the help of their manufacturer. By laying out the size, packaging design, branding, cut lines, glue, and more, dielines are essentially a blueprint for the printing and die cutting process.

Die Lines 101

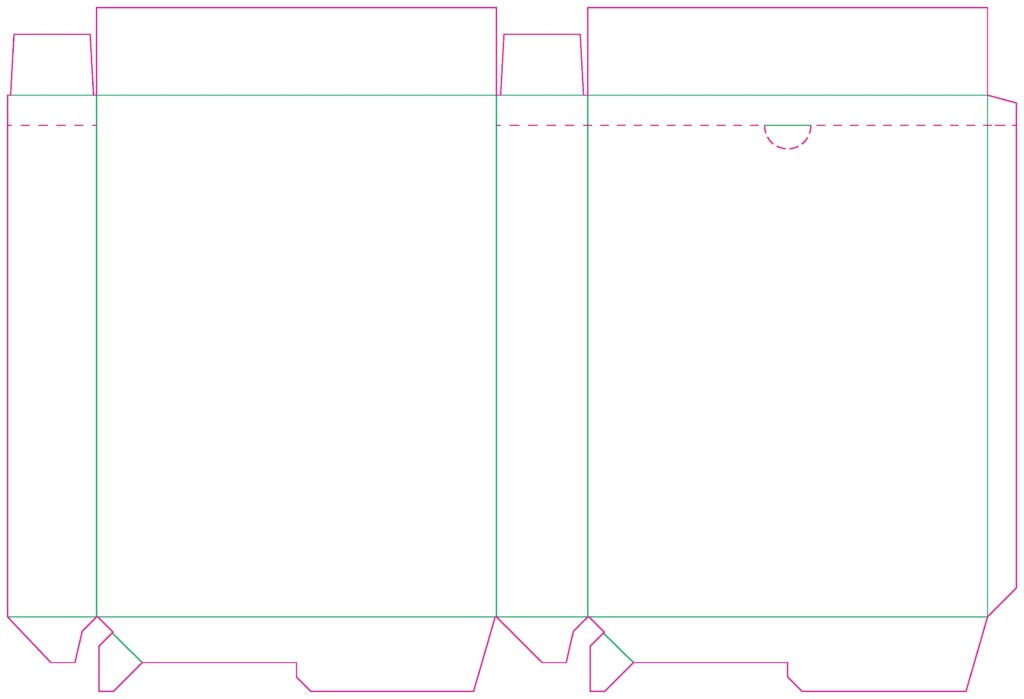

Along with the visual designs, the dieline will also lay out the fold lines, cut lines, perforation lines, bleed lines, safety lines, and glue tabs. In order to get the perfect cut for your custom box, you’ll want to be familiar with these key terms.

Fold Lines: lines on a dieline indicate where to fold for the box’s assembly

Cut Lines: line on a dieline that identify where the die cutter will make cuts

Perforation Lines: line on a dieline that indicate where a tear off perforation will be made

Bleed Lines: line on a dieline identifying the extra amount of space colors and artwork should extend to in order to avoid art getting cut off or imperfect edges

Safety Lines: dotted line on a dieline that indicate the safest place for artwork to end before risking any art getting cut by the die cutter

Glue Tabs: area on a dieline that identify where glue will be applied

Die: cutting tool attached to a die cutter that is customized to shape materials such as paper or cardboard into specific shapes

When creating eCommerce and retail product packaging, the devil is in the details. It’s important to create vector designs with accurate measurements. Pro tip: when creating a new die line, remember to print a protype to see your packaging design before printing a high-volume.

In the dieline example below, you’ll see pink dotted perforation lines, pink solid cut lines, and green solid folding lines.

The Die Cutting Process

Designing your packages die line is one of the earliest steps in the custom packaging printing process. To break it down simply, first you need to create a die line and create or reuse and existing die to match your dieline. After this custom box prep is complete, you’ll perfect a prototype then start printing your final package! Once your packages are printed, they’ll be sent off from your printer to be packed.

Our favorite step in the die cutting process is watching the die cutter in action. Check out our Original Heidelberg Cylinder that’s been converted to a die cutting press.

Get the Perfect Cut with BR Printers

BR Printers has worked with some of the nation’s largest brands to turn their 2-dimensional dieline file into a stunning 3-dimensional package. Whether you’re learning about food packaging or folding cartons for beauty products, we’re here to help. Along with print and marketing solutions, at BR Printers we provide a custom luxury packaging solution. If you want to collaborate with people who can go above and beyond your product packaging needs in a timely manner, contact us today.